Flow Meters

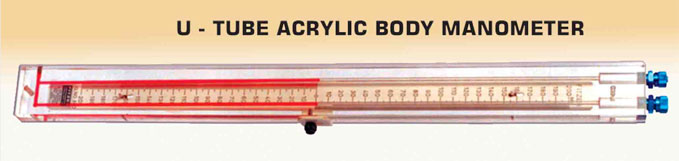

U-Tube Manometers are versatile, economical instruments for the measurement of pressure, vacuums or differential pressures. Pressure measurements are accomplished by balancing a vertical head of indicating fluid with the pressure to be measured. As there are no cams, gears or levers to operate in the manometer, the readings obtained are always accurate.

Principle:

The U Tube Manometer, have “U” shaped tube, half filled with liquid (Water / Mercury / SP Gr. 0.81). When both the tubes are open, the liquid is at the same height in each leg (Tube / Limbs). When positive pressure is applied to one leg which is the sum of the reading above and below zero, tells you the pressure. When vacuum is applied to one leg, the liquid rises in that leg and falls in the other. The difference in the height indicates the amount of vacuum. The U Tube Manometer, consisting of two Glass Limbs. Stainless Steel / Brass Connecting fittings mounted on a metallic frame, provided with White Acrylic Scale with zero at the center. The U Tube Liquid Column Manometer we provide is used to determine Velocity and Static Pressure, Leakage, Fan Efficiency and Gas Pressure. The Manometer will be protected with transparent acrylic front cover fix with Aluminum frame and external zero adjustment Knob / Drain Plug / Fill Plug will Be Provided

Features

Process Connection: Nozzle type and Screwed type Available in 1/8” BSP/ NPT, ¼” BSP/NPT.

Mounting: Wall Mounting, Table (Stand) Mounting and Panel Mounting.

MODEL: Manometer will be provided with C.I. 3 legged Stand, having 3 Nos leveling screw and attached Round Type Bull Eye Spirit Level.

Standard Ranges: Unit: mmWc, mm of Hg, Equivalent is PSI and other units as per Customers’ requirements.

| For Glass Tube : | 250 - 0 - 250 mm | 500 - 0 - 500 mm |

| 300 – 0 – 300 mm | 400 – 0 – 400 mm | |

| 600 – 0 -600 mm | 800 – 0 – 800 mm | |

| 750 - 0 - 750 mm | 1000 - 0 - 1000 mm | |

| For Acrylic Body : | 50 - 0 - 50 mm | 100 - 0 - 100 mm |

| 150 - 0 - 150 mm | 200 - 0 - 200 mm |

Manometer can also be manufactured for range above 2000 mmwc to 20000 mmwc against order.

Are provided with a well which has a much larger area to that of the manometer tube and the level variation in the well is negligible to the rise in level in the Manometer tube. The Scales of these manometers are also prepared in such a manner as to compensate the level change in the well. Multi tube manometers with individual wells are used for multiple reading of pressure and also suitable for tank level gauging with purge tube. It is used for the precision measurement of pressure, vacuum, differential pressure for flow and liquid level measurement.

In general consisting of Stainless steel fittings, Glass Limbs mounted on a metallic frame, provided with White Acrylic / Aluminum Scale with zero at the bottom. The Manometer will be protected with transparent front cover and external Zero Adjustment Knob will be provided.

Range: From 0 to 10000 mmWc, VAC 0 to -760 mmHg

Process Connection: Nozzle type and Screwed type Available in 1/8” BSP/ NPT, ¼” BSP/NPT.

Mounting: Wall Mounting and Table (Stand) Mounting

MODEL : Manometer will be provided with C.I.3 legged Stand, having 3 Nos leveling screw and attached Round Type Bull Eye Spirit Level.

Arrangements: Fill Plug, Drain Plug, Leveling Screw, Spirit Level,‘0’ Adjustment Knob.

Range :

| For Glass Tube : | 0 - 250 mm | - 500 mm |

| 0 - 750 mm | 00 - 1000 mm | |

| For Acrylic Body : | 0 - 100 mm | 0 - 200 mm |

| 0 - 300 mm | 0 - 500 mm |

Inclined Tube Manometer utilize expanded scales for unusual sensitivity for fast, easy reading of low pressures, draft of small differential pressure. Solid acrylic body portable manometers are fabricated from 1" thick, clear acrylic block. Unbreakable, stable and free of distortion, consisting of drilled-in indicating limbs & tanks with high precision & accuracy. An acrylic/aluminium scale is provided which is calibrated in the specified range.

Mounting: Wall Mounting, Table Mounting Plush Or Panel Mounting Available

Standard Accessories Scale '0' knob, Spirit Level, Drain Plug, Connecting Rubber/PVC Tubing Connections and Panel Mounting Holes provided

Connection Options: Nozzle Type, Female Screwed Type, Male Screwed Type

Range :

| -1 to +5 mmWc | 0 to 50 mmWc |

| -1 to +10 mmWc | 0 to 75 mmWc |

| -5 to +5 mmWc | 0 to 100 mmWc |

| 0 to 10 mmWc | 0 to 150 mmWc |

| 0 to 15 mmWc | 0 to 200 mmWc |

| 0 to 25 mmWc | 0 to 500 mmWc |

| 0 to 30 mmWc | 0 to 1000 mmWc |